Understanding the Evolution of Cordless Angle Grinders

The advancement of the cordless angle grinder has transformed fabrication jobs by reducing reliance on fixed power sources. These tools utilize advanced lithium-ion batteries to offer similar efficiency to conventional models while permitting unrestricted mobility. Professionals prioritize ergonomic designs with improved handle and shock mitigation elements, guaranteeing accuracy during prolonged application. Furthermore, developments in engine technology have significantly extended operational duration, making them ideal for industrial tasks.

Key Advantages of 20V Angle Grinder Systems

A 20v angle grinder achieves the perfect ratio between strength and portability, rendering it a popular option for both DIY enthusiasts and contractors. The 20V system performs in providing steady torque for polishing dense surfaces like metal or stone. Unlike less powerful devices, 20V systems retain optimal efficiency even under extended load, minimizing thermal overload and energy loss. Numerous brands provide interchangeable batteries, enabling users to smoothly switch between equipment without interruptions. This attribute enhances productivity on hectic worksites.

Identifying the Best Angle Grinder for Your Needs

Picking the best angle grinder involves evaluating key aspects such as disc size, engine capacity, and primary tasks. For intensive operations, opt for devices with greater amperage and robust build to endure rigorous utilization. Conversely, portable options with adjustable protections are ideal for precision work like engraving. Manufacturers frequently include protective mechanisms such as electric brakes and lock-off buttons to mitigate accidents. Moreover, consider guarantee conditions and availability of spare components to guarantee long-term reliability.

Mastering the Angle Grinder Tool for Precision Work

An angle grinder tool serves as a multipurpose option for slicing, grinding, and sharpening surfaces ranging from ceramic to rebar. To achieve flawless finishes, operators must select the appropriate attachment for each job—abrasive wheels for concrete or grinding wheels for aluminum. Adequate technique involves holding a stable handle and using even load to avoid irregular textures. For complex operations, lowering the rotation rate and utilizing dedicated accessories enhances control. Frequent upkeep, including lubrication, prolongs the equipment’s lifespan.

Optimizing Performance with Variable Speed Angle Grinders

The variable speed angle grinder differs by offering modifiable RPM settings, enabling users to modify functionality to unique materials and tasks. This feature avoids harm to delicate workpieces like sheet metal while maximizing output on rigid substrates. For instance, reducing the speed when smoothing plastic avoids melting, whereas higher speeds expedite shaping operations. High-end units integrate smart feedback systems that intelligently modulate power based on resistance, ensuring uniform outcomes.

Enhancing Safety Protocols for Angle Grinder Use

Despite their usefulness, angle grinders present considerable safety risks if used carelessly. Essential measures include using protective accessories such as eye protection, hand protection, and fire-resistant clothing. Consistently check the grinder for defects before use, confirming the guard is securely attached and the wheel is intact. Avoid forcing the tool through materials, as this raises the likelihood of recoil. When replacing attachments, disconnect the power source to avoid inadvertent startup. Adhering to these practices reduces job site incidents.

Future Innovations in Angle Grinder Technology

The next generation of angle grinders anticipates revolutionary advancements, including AI-powered technologies that anticipate servicing demands and optimize settings for optimal performance. Wireless integration may allow live performance monitoring via digital platforms, allowing users to track usage patterns. Furthermore, advancements in power cell technology could produce quick charging systems and increased capacity, enhancing operational time significantly. Eco-friendly components and quiet features are also anticipated to achieve traction in answer to regulatory regulations.

Conclusion: Investing in the Right Angle Grinder

Whether undertaking professional projects or home improvement endeavors, investing in the right angle grinder requires detailed evaluation of power, versatility, and protection attributes. By focusing on long-lasting construction, ergonomic designs, and cutting-edge systems, users can attain exceptional performance while reducing hazards. Stay updated about new trends to utilize enhancements that match their specific demands. In the end, a carefully selected angle grinder serves as an indispensable asset in achieving professional outcomes.

Mr. T Then & Now!

Mr. T Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Loni Anderson Then & Now!

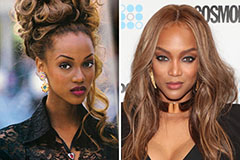

Loni Anderson Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!